Extrusion Coating Concept - PROMEA Engineering Srl

Main menu

Extrusion Coating Concept

High-

The basic concept of extrusion coating technology is to produce and convert a plastic film in one operation step. This technology does not use any pollutant solvents and adhesives in compliance with many strict pollution control regulations of the food-

Generally, the process of extrusion coating of different laminates (composites) with a film of thermoplastic material is the following:

In the extruder, the thermoplastic polymer (generally PE or PP) is processed into a homogeneous melt and formed into a melt web in the die head;

The material web (substrate) is fed into the nip between the laminator roll and pressure roll;

The melt web applied to the substrate sticks as a film to the surface of the substrate. As a result of the contact pressure operated by the pressure roll and the temperature of the melt, the plastic film and the substrate are completely adhered to each other.

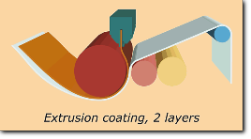

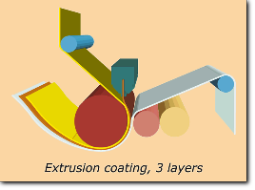

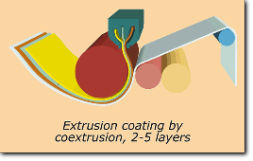

Depending on the structures being combined (co-

High quality composite films are obtained by coating thermoplastic materials with substrates such as nonwovens, plastic films, textiles, paper, aluminium foil, etc. These extrusion coated products find a broad application in the following industries:

Hygiene and health care (cloth-

like backsheet film for baby and adult diapers, incontinence garments, bandages, disposable drapes, gowns, etc.) Building (roofing, house wrapping, insulation, wipe-

clean wallpapers) Packaging (beverage packs, foodstuffs, etc.)