Winders - PROMEA Engineering Srl

Main menu

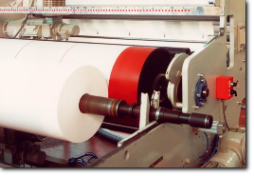

Winders

Perfectly wound rolls are the beginning and the end of each conversion process!

Winders series PW are known for their compact design and rugged construction. Their adaptability to a wide range of processes and materials such as tissue paper, plastic films, laminates, aluminium foil, nonwovens, etc. make these winders suitable to most applications. They are designed to be integrated with an existing line or combined with other Promea equipment to create a completely new process line.

PW/CS Cantilevered Shaft Unwinders

Promea Engineering's turret winders provide excellent web handling for wrinkle-

A speed-

Lay-

An operator-

Reel diameter: upon customer request

Reel width: up to 800 mm

Max reel weight: 100 Kg

Core diameter: 3" -

6" - 8" Mechanical speed: 400 m/min.

PW/DS Double Supported Turret Winders

Promea Engineering's turrets winders provide standard or customized solutions for winding needs that range from the simplest to the most sophisticated. PW/DS series offers standard features, like:

Stable design to avoid vibrations

Servo drive control for precise winding speed even during changeovers

Perfect parallelism of lay-

on carriage to achieve precise cylindrical rolls Linear lay-

on assembly for optimum lay- on pressure control Accurate reel slitting (shear, score, razor)

Operator-

friendly console to easily preset and control all winding parameters

The winding action is controlled by a PLC that provides information such as reel diameter, dancer roll position and master machine speed used to automatically set torque and speed/pressure values of shafts and lay-

Reel diameter: upon customer request

Reel width: up to 3000 mm

Core diameter: 3" -

6" - 8" Mechanical speed: 400 m/min.

Other Features and Options

All of our turret winders are available with center wind, surface wind and minimum gap capabilities.

Options include pneumatic slit/trim assemblies, trim winders, oscillating rewinds, reverse winding, tapeless transfer, dancer tension control, driven bowed roll for lightweight film structures, automatic shaft handling and extraction.

PW/HS Horizontal Surface Winders

These winders are based on surface wind technology, and designed for the production of quality wrinkle-

Other Features and Options

Web cut system with linear bearing guide, cylinder cushions and self-

aligning couplings Oncoming shaft acceleration to match line speed prior to web contact for cut and transfer

Pure surface winding with optional center wind assist.

Shafts magazine: optional

Inline slitting (shear, score, razor): optional

Shaft pull out device: optional

Shaft handling device: optional

Modem connection: optional

Reel diameter: 600 mm. with 3" core, other diameters available on request

Reel width: up to 3000 mm

Core diameter: 3" (6" optional)

Mechanical speed: 400 m/min.

Thickness range: 14 µm up to 300 µm